Paint Booth Filter

Premium Paint Booth Filter Solutions for Superior Filtration in Gujarat

Introduction: High-Performance Paint Booth Filters for Industrial Excellence

Paint booth filters are indispensable for maintaining clean air, protecting your workforce, and ensuring high-quality finishes in industrial applications. Designed to capture overspray and contaminants, these filters are essential for industries ranging from automotive to woodworking. Whether you’re in Ahmedabad, Baroda, Surat, Rajkot, or Gujarat, our comprehensive range of paint booth filter systems meets every industrial need.

What is a Paint Booth Filter?

A paint booth filter is a specialized filtration solution for capturing paint overspray and airborne particles during painting processes. It ensures a clean working environment, better product finish, and compliance with environmental regulations.

Key Features:

- High filtration efficiency

- Extended lifespan

- Easy installation and maintenance

- Available in multiple configurations

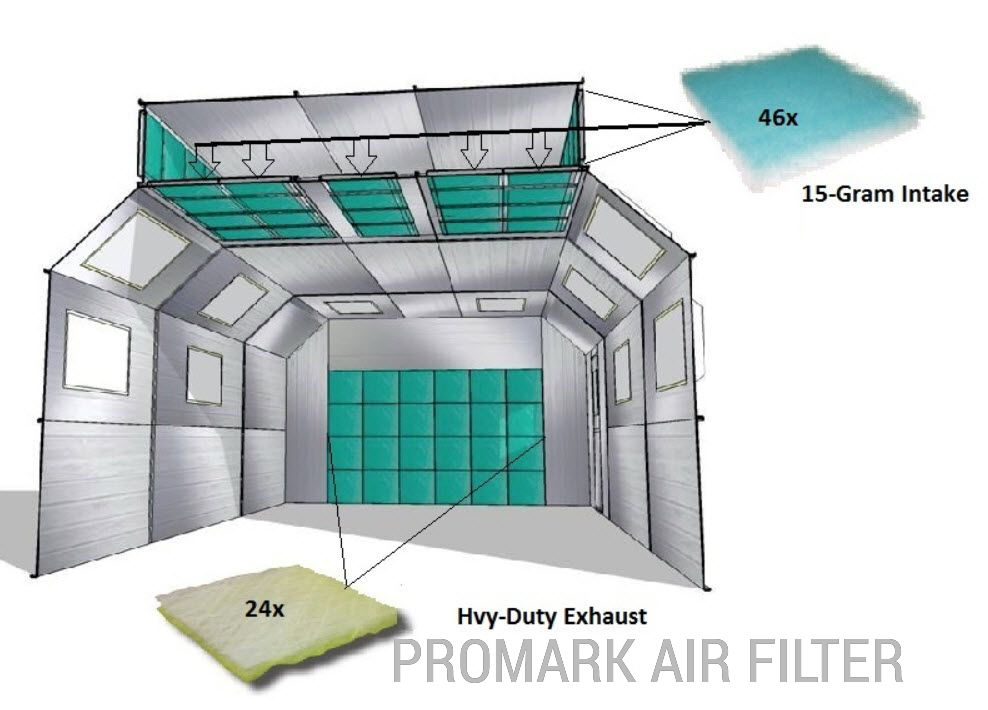

Types of Paint Booth Filters

Our product lineup includes a variety of paint booth filters tailored to specific applications.

1. Dry Paint Booth Filters

Ideal for industries requiring dry filtration systems, these filters utilize pleated media or baffle filters to capture particles efficiently.

- Applications: Automotive, woodworking, furniture manufacturing

- Advantages: Cost-effective, reusable baffle filters, low maintenance

2. Water Wash Paint Booth Filters

Equipped with a vertical water screen and recirculating water system, these filters effectively remove sticky paint overspray.

- Applications: Large-scale painting facilities, automotive production

- Advantages: High efficiency, sustainable water usage, alkali-resistant

3. Wet Scrubber Systems

Wet scrubbers integrate liquid mediums to neutralize and recover pollutants from exhaust gases.

- Applications: Chemical, pharmaceutical, and electronics industries

- Advantages: Excellent for high-temperature and moist gas environments

Our Expertise in Paint Booth Filtration Systems

We take pride in being a leading manufacturer and supplier of paint booth filters in Gujarat, catering to cities like Ahmedabad, Baroda, Surat, and Rajkot. Our products are built with the highest quality standards, ensuring:

- Compliance with international emissions regulations

- Customization for specific industrial needs

- Competitive pricing without compromising quality

Applications of Paint Booth Filters

Our filters find application in a variety of industries:

- Automotive Manufacturing: Overspray containment and superior finishes

- Woodworking: Dust-free environments for polished results

- Chemical Industry: Containment of hazardous particles

- Metalworking: Durable filtration under high-temperature operations

Why Choose Us?

- Customizable Solutions: Filters designed to match specific industrial requirements.

- Top-Notch Materials: Use of high-quality polypropylene, stainless steel, and eco-friendly materials.

- Expert Support: Professional consultation for selecting the right filter.

- On-Time Delivery: Reliable supply chain to meet your timelines.

FAQs about Paint Booth Filters

What is a paint booth filter, and why is it important?

A paint booth filter is a specialized filtration solution designed to capture paint overspray, airborne particles, and contaminants during painting processes. These filters are crucial for maintaining a clean environment, ensuring a superior product finish, and meeting environmental regulations. Whether you’re looking for industrial paint booth filters or paint booth filter systems, our solutions offer high filtration efficiency and long-lasting performance.

What type of filters does my paint booth use?

Paint booths typically use one of the following types of filters:

- Dry Paint Booth Filters: Ideal for industries like automotive and woodworking, these filters use pleated media or baffle filters for efficient dust capture.

- Water Wash Paint Booth Filters: These filters use water to remove sticky overspray, ideal for large-scale painting operations in automotive and manufacturing.

- Wet Scrubber Systems: Used for high-temperature environments in industries such as chemical, pharmaceutical, and electronics. At paint booth filter manufacturers, we offer these and other types of paint booth filtration systems tailored to your industrial needs.

How do I choose the right filter for my paint booth?

Choosing the right filter depends on factors like the type of painting process, the environment, and the pollutants you need to capture. Consider the following:

- Dry Filters: Cost-effective and reusable, perfect for general overspray and dust containment.

- Water Wash Filters: Best for sticky overspray in large-scale operations.

- Wet Scrubbers: Suitable for high-temperature and moist environments.

As leading paint booth filter suppliers, we provide expert consultation to help you select the right industrial paint booth filters for your needs.

Why does my paint job have dust in it?

Dust in paint jobs can result from inadequate paint booth filtration, improper filter maintenance, or using the wrong filter type. Ensure you’re using the correct paint booth filter system that meets your application requirements. Regularly replace paint booth filters to maintain optimal air quality and achieve flawless finishes.

What are the different types of paint booth filters available?

There are several types of paint booth filters available:

- Dry Paint Booth Filters: Pleated media or baffle filters for dry filtration.

- Water Wash Paint Booth Filters: Recirculating water systems for high-efficiency sticky overspray removal.

- Wet Scrubber Systems: For high-temperature and moist environments, used in chemical and pharmaceutical industries.

We offer these paint booth filtration systems for diverse applications, including automotive, woodworking, and chemical industries.

How do paint booth filters work?

Paint booth filters work by trapping airborne contaminants like paint overspray, dust, and particles during the painting process. Depending on the type, they use different filtration methods like dry filtration (pleated media), water filtration, or wet scrubbing to ensure a clean working environment and superior product finishes.

What is the ideal time to change a paint booth’s filters?

The ideal time to change your paint booth filters is based on usage frequency, the amount of overspray, and the type of filter. Typically, filters should be replaced when you notice reduced airflow or an increase in dust or contaminants. Regular paint booth filter testing can help determine when it’s time for a change.

How often should I replace my paint booth filters?

The frequency of paint booth filter replacement depends on the type of filter and how often your paint booth is used. For industrial paint booth filters, it’s recommended to replace filters every 3 to 6 months, or when airflow and filtration efficiency drop. Always ensure you’re using high-quality paint booth filters to maintain peak performance.

What are the signs that my filters need replacement?

Signs that your paint booth filters need replacement include:

- Reduced airflow or excessive pressure drop.

- Visible paint overspray buildup in the booth or on products.

- Difficulty in maintaining consistent paint finishes. If you notice any of these issues, it’s time to replace your paint booth filtration system to avoid disruptions in your operations.